Conventional tools

发布时间:2015-01-08 13:15 浏览量:5011

Davis-Lynch's history can be traced back to 1947. It has always been a major global cementing equipment manufacturer since its inception. Company headquarters and main workshop located in Texas. Meanwhile, it also produced some large diameter tools in Singapore. Its representatives and distributors are all over the world.

We are the exclusive agency for Davis-Lynch in China.

The main conventional cementing tools of Davis-Lynch are float collars, float shoes, stage collars and centralizers.

1. Davis-Lynch Float collars:

(1) Float Collar Type 700-PVTS-----This Davis collar comes equipped with a flat concrete surface and load distributor plate for landing and sealing cement plugs. It normally is offered with pin and box thread connections, but it is also available with double-box connections. Both of these designs embody the positiveseal, PDC drillable Davis PVTS spring-operated plunger-type valve molded in place with high strength concrete. When a back-pressure valve is not desired or required in a float collar, Davis has available the Type 701 Baffle Collar (not shown). This collar allows fluid flow in either direction and provides a strong concrete surface to land and seal cement plugs. It is often run in tandem with the Davis Type 501 DV-PVTS double-valve, down-jet float shoe.

(2)Float Collar Type 700 LAP/N-----This float collar with a heavy duty “tooth like” insert incorporated, a bottom cementing plug with heavy duty inserts incorporated on top and bottom, as well as a top plug with a heavy duty insert incorporated on bottom. The unique angled tooth design of the system allows for easy engagement between plug and collar, as well as between plugs.

(3)Lock-Down Anti-Rotation Plug System Type LAP----Available for both surface launch and sub sea launch applications, Davis offers the Type LAP plug system. The Type LAP system incorporates our first generation of mechanism to prevent plug rotation while drilling out. This system is still used on some surface launch applications involving specialty float equipment (such as auto-fill types), and is available through a joint venture with BJ Services Co. for sub sea applications. BJ Services Co. has incorporated the Davis Type LAP mechanism into their respective sub sea launch plugs, so the BJ plugs can be run with Davis Type LAP float collars, and provide an effective means to prevent rotation while drilling out. The system features a float collar that incorporates a threaded type receiver to receive a collet type insert. A bottom plug with collet insert on bottom, and threaded type receiver on top of plug. The top plug features a collet type insert on the bottom end. The collet feature allows for the bottom plug to latch into the float collar, as well as for the top plug to latch-in to the bottom plug. Once latched in, right hand rotation during drill out tightens up the engagement of the plugs and collar, with the threaded profiles on the collet and receiver.

2. Davis-Lynch Float shoes:

(1)Float Shoe Type 500-PVTS-----This shoe features a strong, rounded concrete nose that aids in guiding the casing string to bottom and incorporates the PVTS back-pressure valve assembly. These features make this Davis shoe highly preferred for conventional cementing jobs.

(2)Down-Jet Float Shoe Type 501-PVTS-----Along with all the features incorporated into the Type 500-PVTS float shoe, the popular Type 501-PVTS model features properly drilled and angled down-jet ports. The even distribution of fluid through these raised ports delivers to the user several advantages, including the added assurance that circulation can be established when casing becomes plugged during running or is landed on bottom. The angle of the ports assists if casing has to be washed to bottom, and the spacing of the ports assists in breaking up or preventing cement channeling.

(3)Down-Jet Set Shoe with Lug Nose Type “S”-----This Davis shoe comes with a special drillable lug nose for use when casing is run as a liner, lowered on drill pipe and set on bottom. When bottom is contacted, the nose piece will prevent the casing from rotating when the drill pipe is released from the liner. This lug nose design can also be incorporated into self-filling shoes.

(4)Needle Nose Float

Shoe-----Field-proved for over 20

years, the Davis Needle Nose Float Shoe has provided operators

with an aid to run casing in adverse conditions. With its tapered

aluminum nose, it has been extremely effective for running casing through

tight spots, different geometric sections in the wellbore, and previous

casing strings that have been damaged. It incorporates down-jet

ports that create turbulent flow at the shoe for washing, conditioning, or

cementing. The Needle Nose Shoe can be equipped with the Davis

Type PVTS valve, which has been proven to meet or exceed API RP

10 F category III C., or with a self-filling type valve.

3. Davis-Lynch stage collars:

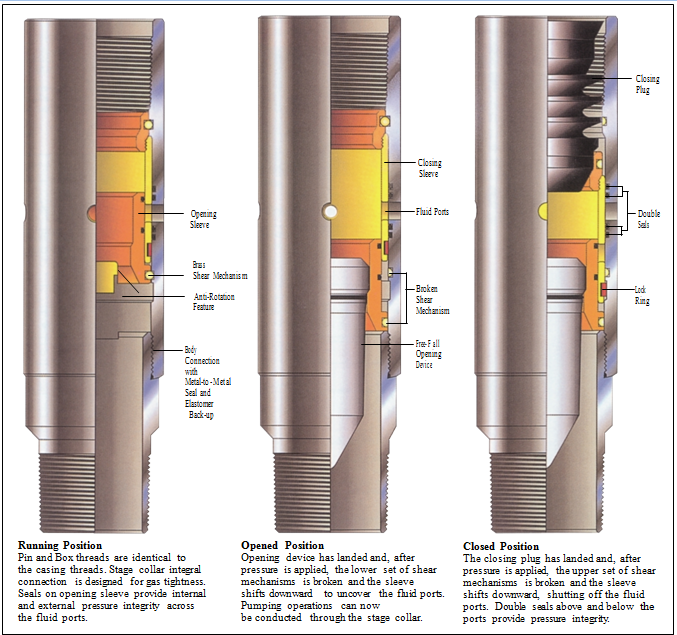

(1)Type 778 MC Mechanical Stage Cementing Collar:

While now established as a fieldproven tool, this tool continues to be the subject of research and development to find new materials for faster drill-out time, greater PDC bit drillability and better metal-to-metal sealing.

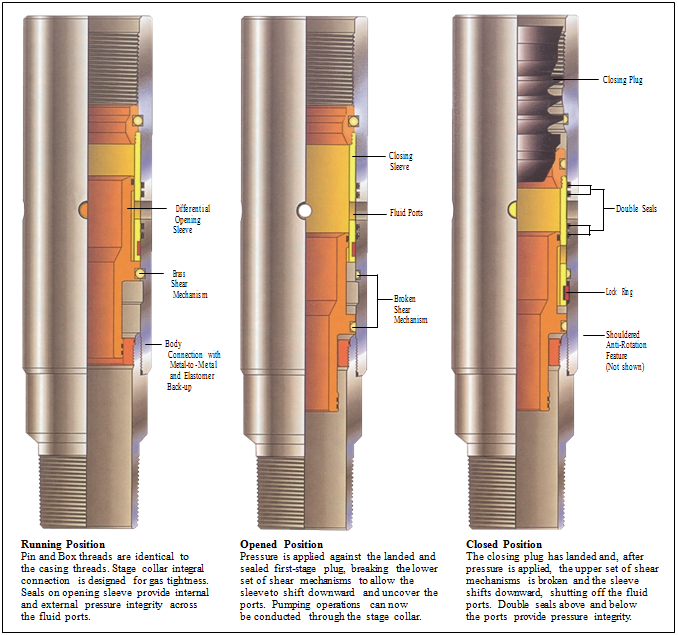

(2)Type 777 HY Hydraulic-Opening Stage Cementing Collar:

This stage collar features an opening sleeve with area differences on opposite ends that allows it to be manipulated hydraulically. The closing sleeve is identical to the one contained in the Davis Type 778 MC Mechanical Stage Cementing Collar. The development and introduction of this model was spurred on by the tremendous upswing in horizontal drilling activity that has occurred in recent years. The hydraulic-opening feature makes this tool’s use very practical in horizontal wells.

The elimination of the need to use a mechanical opening device has several other merits. Casing runs in highly deviated wells can now be two-stage cemented without having to use continuous displacement type plugs. In certain applications, liners run with drill pipe can be run in conjunction with one or several inflatable packers and used to isolate and selectively cement certain casing intervals. Slotted or predrilled liner can be run below a Davis inflatable packer/hydraulic stage collar assembly, allowing cement to be pumped above the packer and isolated from highly sensitive producing zones.

(3)Type 778-100 Packer Stage Cementing Collar:

This widely accepted Davis product combines an inflatable packer and a stage cementing collar into a singular unit. The stage collar portion of this tool uses the same sleeve and mechanical systems as the field- proven Davis Type 778 Stage Cementing Collar.

The packer portion of this tool uses the same element design as the field- proven Davis Type 100 Integral Casing Packer. This element consists of an innertube housed and protected by continuous, mechanically end- anchored, spring-steel reinforcing strips that are leafed on top of each other. These strips are encased in an oil-resistant outer rubber. Expansion is obtained by injecting fluid into the innertube. This injection forces partial un-leafing of the steel strips which in turn stretches the outer rubber until it effects a full-length seal against the bore it is run in, whether cased or open hole.

While the packer is expanding, the bottom end of the element is drawn up on a ratchet-type locking mechanism. This feature is intended to keep the element mechanically expanded so it can provide some form of sup- port in the event of hydraulic failure.Once inflation pressure is reached, simultaneous sealing of the fluid injection inlets and opening of the cementing ports occur. This action allows the immediate introduction of fluid to the annulus after the packer is set. The inflation of the packer also serves to center the tool in the well- bore, leading to uniform distribution of cement as it exits the casing.

Although the combination packer stage collar serves two purposes, it is only one tool. This means that it can be serviced by one person, which eliminates the cost of the second person who would be required if a stage collar and inflatable packer were individually purchased from two separate companies.

4.Davis-Lynch centralizers:

(1)Davis Non-Welded Centralizer-----Davis offers a full line of patented, non-weld centralizers. The centralizers feature a unique interlocking adjoinment between the end collar and bow spring, which makes for a strong singular unit. Davis Type “NW” centralizers are designed to exceed the performance requirements of API Specification 10D for both starting and restoring forces.

(2)Davis Non-Welded Turbolizer-----This is a

centralizer with metal fins installed on the bows to help induce turbulence

in the cement slurry during pumping operations. Like the spring

bows, the fins are made of heat-treated alloy steel. This makes them

flexible, which minimizes damage while moving downhole. The Davis

Turbolizer incorporates the same non-welded end collar-to-spring-bow interlocking adjoinment as the Davis centralizer. Turbolizers are

available in the same sizes and bow heights as centralizers. As with the Davis centralizer, turbolizers can be

manufactured with a built-in stop device. These items are available

on special order.

(3)Davis Close-Tolerance Bow Spring Centralizer-----In applications for running casing in close tolerances or slim holes, Davis offers a special type bow spring centralizer for these requirements. To provide optimum performance in close-tolerance holes, these centralizers feature low starting forces and high restoring forces. Centralizers consist of a solid type end collar for slipping over the pin end of casing joint.

(4)Davis Spherical Stand-Off Device-----A new product that Davis is introducing is a spherical shaped standoff device. This device is designed to promote positive stand-off, and significantly reduce the drag forces that are normally associated with other positive stand-off devices.