Liner Hanger

发布时间:2015-01-08 13:14 浏览量:3088

We provide foreign famous liner hanger equipment with service. The product line is backed with 35 years of engineering technology and expertise and manufactured to ISO 9001:2000 standards and COR certified. They provide and service a complete product line of liner hanger equipment based on their proprietary designs as well as other world wide recognizable standards.

The liner hanger’s sizes range from 2⅜ inches (63 mm) through 30 inches (762mm).

Usually, the liner hanger contains these parts below: Liner-top packers, liner hanger, plugs, landing collar, tieback seal nipple, liner tieback packer and some running tools

Liner- Top Packers:

The LINER LAP PACKER, ROTATIONAL (LLPH-R) with hold downs is a versatile liner lap packer which can be used in a number of different applications. It is most often placed at the top of a liner which is to be cemented. Setting the LLPH-R after cementing allows the operator to reverse excess cement out of the hole without exerting pressure on the formations below the top of theliner.

The LLPH-R prevents gas migration through the cement as it is setting up.

The LLPH-R is available with or without hold-down slips and comes standard with reinforced Nitrile rubber pack-offs or with optional HNBR pack-offs. A TechWest Liners’ premium HT/HP(High Temperature /High Pressure) and steam injection seal pickoffs are also available for the LLPH-R.

The LLPH-R is run with an MR Setting Tool screwed into its barrel using a left-hand thread and floating nut. The setting tool is released by right-hand rotation. The setting tool is lowered, forcing the Tieback Receptacle (Unit 122) downward and expanding the pack-off to set the LLPH-R. A ratchet ring in the LLPH-R locks the pack-off in the set position.

When used as an isolation device for screens, the LLPH-R (without hold-down slips) may be retrieved by running a spear to catch the inner barrel of the LLPH-R.

The packer is set by providing a compression force to the top of the available Tieback Receptacle.

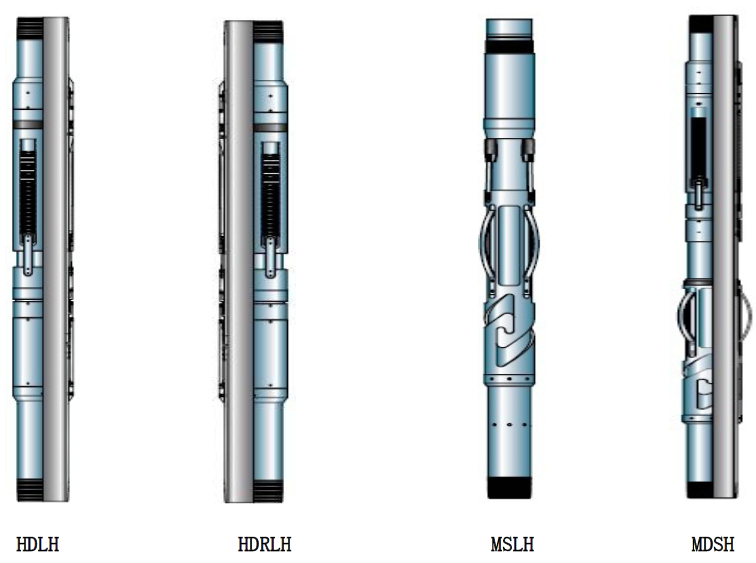

Liner Hanger:

The HYDRAULIC DOVETAIL LINER HANGER (HDLH) is a premium hanger with an integral body. The hanger mandrel is machined from heavy wall mechanical tubing and treated to the required grade. Integral construction eliminates all internal connections which provide maximum pressure ratings and liner hanging capacity.

The HYDRAULIC DOVETAIL ROTATING LINER HANGER (HDRLH) is a premium hanger with an integral body. The hanger mandrel is machined from heavy wall mechanical tubing and treated to the required grade. Integral construction eliminates all internal connections which provide maximum pressure ratings and liner hanging capacity. This premium liner hanger can be rotated into place, set and then rotated through the liner cementing operation.

The MECHANICAL SET LINER (MSLH) are used to suspend cemented and uncemented liners off bottom. Designed for heavy duty service, they are capable of successfully suspending long liners. The MSLH is available with a one-piece integral barrel for maximum pressure integrity. Large bypass lessens pressure build-up during run-in and cementing operations.

The MECHANICAL DOVETAIL ROTATING SLIP HANGER (MDRSH) is a premium hanger with an integral body. The hanger mandrel is machined from heavy wall mechanical tubing and treated to the required grade. Integral construction eliminates all internal connections which provide maximum pressure ratings and liner hanging capacity. The MDRSH once in position can be rotated through the liner cementing operation.

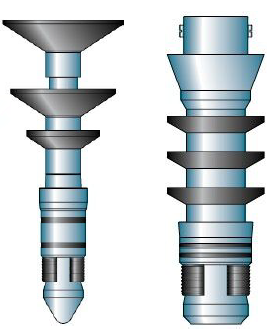

Landing Collar:

The PDP PUMP DOWN PLUG (PDP) with Rotation Prevention Clutch on the nose of the plug lands, and locks in place in the seat of the liner wiper plug. The plugs then land, latch, and seal in the PLC landing collar.

The LINER WIPER PLUG (LWP) with Rotation Prevention Clutch on the nose of the plug lands and locks in place in the seat of the landing collar. Both the Pump Down Plug (PDP) and the LWP act to hold pressure from above and below.

The HYDRAULIC LANDING COLLAR (HLC) has an internal ball seat, and is run with a Hydraulic Dovetail Liner Hanger (HDLH). The HLC is run two or three joints from the shoe, and is used to land the Liner Wiper Plugs (LWP). The LWP provides a pressure seal from above and below and are easily PDC drillable.

The MECHANICAL PLUG LANDING COLLAR (MPLC) is run two or three joints from bottom, and is used to land the Liner Wiper Plug (LWP). The LWP provides a pressure seal that holds pressure from above and below and are easily PDC drillable.

The DRILLABLE BALL SEAT COLLAR (DBSC) can be used anywhere where it is desired to plug the bottom of the casing for any reason to ether set hydraulic equipment above or inflate packers that requires the plugging of the casing string.

Tieback Seal Nipple:

The TIEBACK SEAL NIPPLE (TBSN) has proven to be a superior method of extending the liner to the surface of the well. Using the polished bore receptacle of the Setting Collar (SC) or the Liner Lap Packer (LLPH) packer, this assembly facilitates the entry and subsequent seal of the nipple into the bore.

The TBSN is run at the bottom of the liner extension. Depending on the application, it employs either a premium Aflas or Chevron-type unitized seal assembly, or a series of o-rings. Both designs deliver a solid seat and permanent seal.

The orifice collar normally included in the liner extension assembly is positioned one joint above the seal nipple. This prevents hydraulic blockage as the seal is engaged in the receptacle, and allows the liner extension to fill at a predetermined rate as it is run. The orifice collar also serves as a stop for the cement plug and is constructed of drillable materials.

Liner Tieback Packer:

The LINER TIEBACK PACKER. ROTATIONAL (LTBP-R) is a high-pressure seal at the top of a cemented or un-cemented liner. It is run on drill pipe and/or casing, and landed in a receptacle at the top of the liner. In most applications a type Tieback Receptacle is run with the packer providing for future tieback.

The LTBP-R is run after the liner is set, so that maximum annular flow is achieved at the liner top during cementing. This is possible because there is no restriction like that associated with a conventional liner top packer.

The packer and accompanying hold-down slips are set by applying weight. The setting tool is retrieved with the drill pipe. When set this packer will seal in the liner receptacle and pack-off in the casing to isolate the liner top, holding securely against pressures from above or below. The premium seal pack-off provides a seal against high pressure and high temperatures.

Except those, we also offer some running tools, float collar and float shoe, cement head and so on.

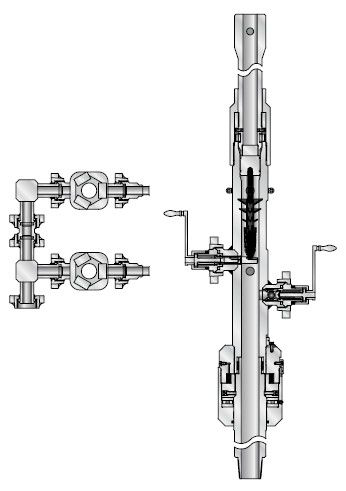

Running Tool:

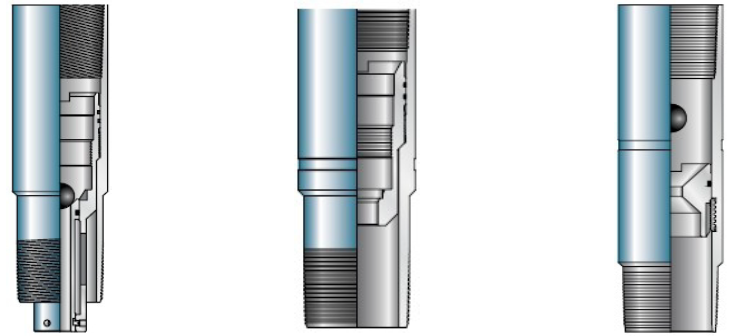

FloatCollar and Float Shoe:

Cement Head: