1、Stage collar running and supervising service.

发布时间:2015-01-08 13:48 浏览量:7774

For over 20 years, Davis stage cementing collars have been used by operators for their special applications. Now Davis offers three stage collar designs: a mechanically opened tool, a hydraulically opened tool, and a mechanically opened tool with a built-in inflatable packer.

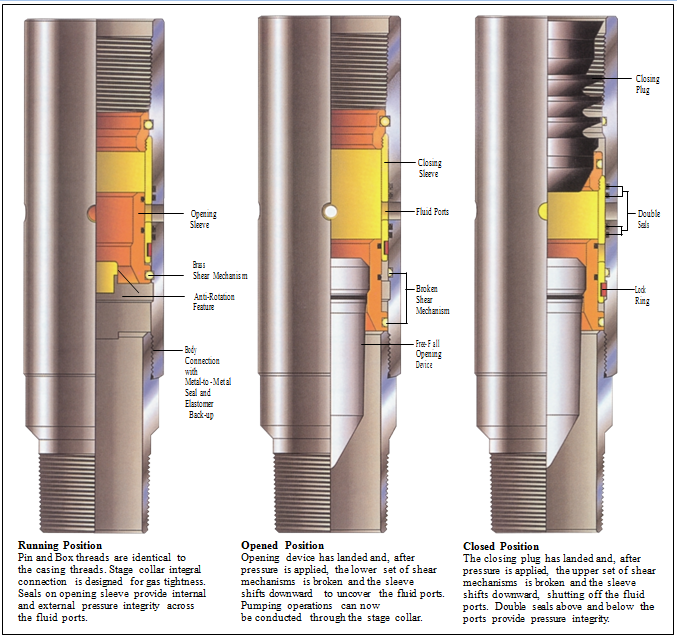

Type 778 MC Mechanical Stage Cementing Collar :

While now established as a field-proven tool, this tool continues to be the subject of research and development to find new materials for faster drill-out time, greater PDC bit drill-ability and better metal-to-metal sealing. Features of the 778 MC Stage Cementing Collar include:

1. Tools can be made from material grades up to 135,000 psi minimum yield, including material suitable for sour gas service.

2. All parts are custom fitted and subjected to extensive quality control standards for maximum performance down-hole.

3. The connection that adjoins the stage collar body and the bottom sub-effects a metal-to-metal seal and engages a back-up elastomer seal, the two of which are designed to provide gas-tight pressure integrity.

4. No welds are used on any portion of the tool.

5. The reduced length of the tool minimizes the effect of bending stresses.

6. The seals providing internal and external pressure integrity are housed in the stage collar body and remain stationary throughout operation, minimizing chances of their being damaged.

7. The pressure-relief design prevents fluid trapping and compression between the opening device and the closing plug during the closing phase of the tool’s operation.

8. The closing sleeve is held in the closed position by an internal lock-ring.

9. Both the opening and closing sleeves lock against rotation for easy drill-out.

10. A minimum amount of aluminum and rubber are the only materials encountered during drill-out.Plug sets for four different cementing applications are available.

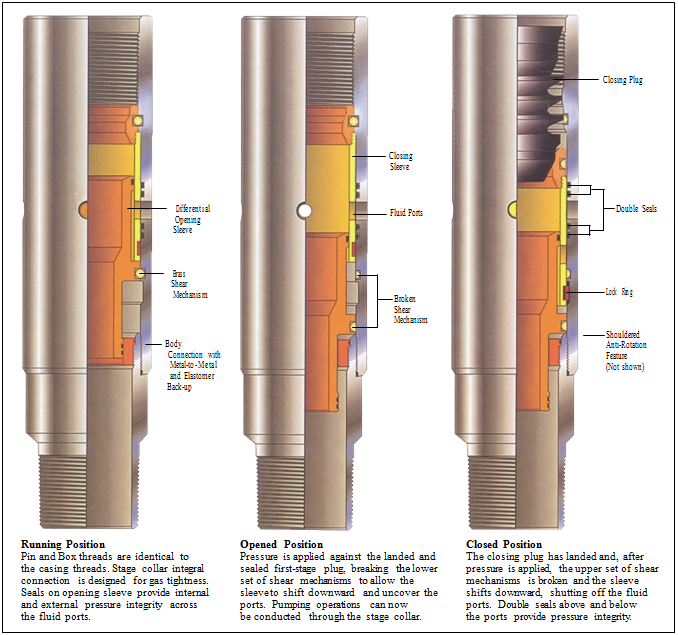

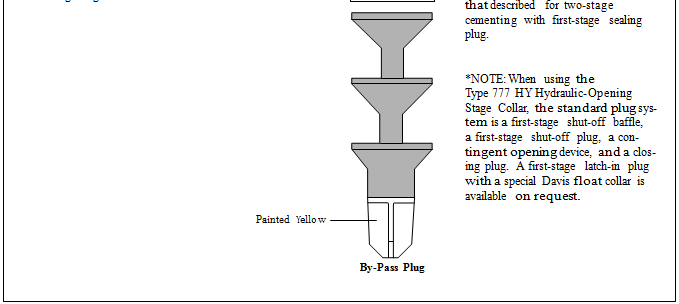

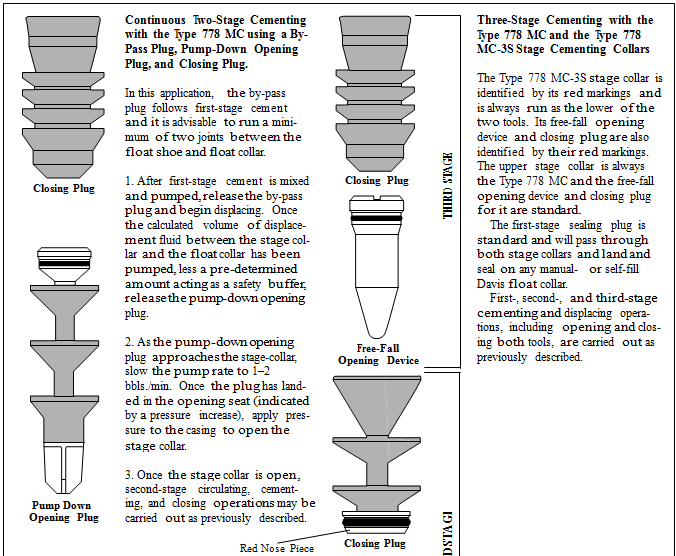

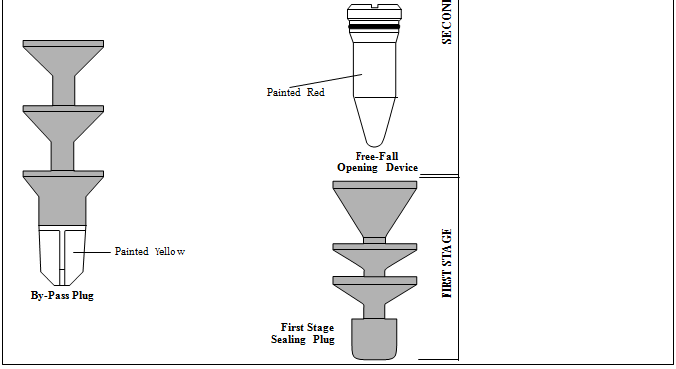

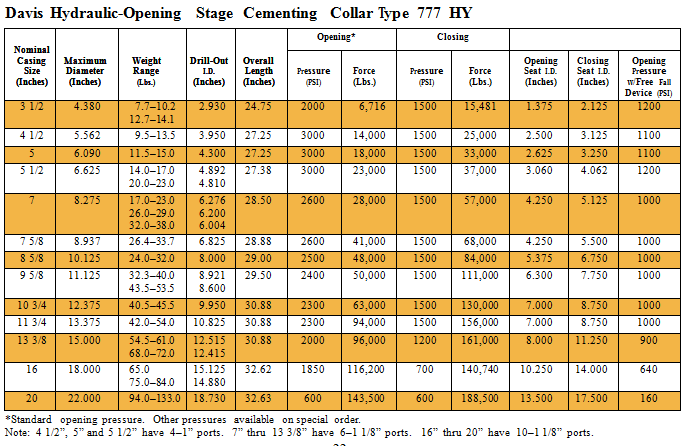

Type 777 HY Hydraulic-Opening Stage Cementing Collar:

This stage collar features an opening sleeve with area differences on opposite ends that allows it to be manipulated hydraulically. The closing sleeve is identical to the one contained in the Davis Type 778 MC Mechanical Stage Cementing Collar. The development and introduction of this model was spurred on by the tremendous upswing in horizontal drilling activity that has occurred in recent years. The hydraulic-opening feature makes this tool’s use very practical in horizontal wells.

The elimination of the need to use a mechanical opening device has several other merits. Casing runs in highly deviated wells can now be two-stage cemented without having to use continuous displacement type plugs. In certain applications, liners run with drill pipe can be run in conjunction with one or several inflatable packers and used to isolate and selectively cement certain casing intervals. Slotted or predrilled liner can be run below a Davis inflatable packer/hydraulic stage collar assembly, allowing cement to be pumped above the packer and isolated from highly sensitive producing zones.

Along with all the features inherent in the 778 MC Stage Cementing Collar, the Type 777 HY offers:

1. Effective differential area on the opening sleeve that generates a high opening force while requiring only optimal pressure to do so.

2.The ability to open immediately upon the completion of first-stage cement displacement.

3.Opening pressure values that can be adjusted at the time of assembly to assure that all inflatable packers or other hydraulic tools present in the casing string will be triggered at the correct juncture.

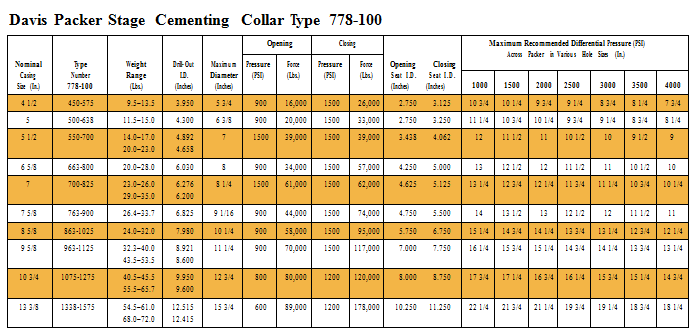

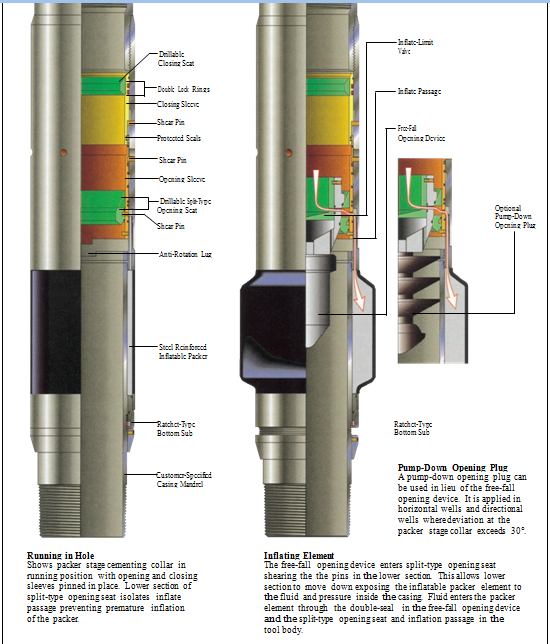

Type 778-100 Packer Stage Cementing Collar:

This widely accepted Davis product combines an inflatable packer and a stage cementing collar into a singular unit. The stage collar portion of this tool uses the same sleeve and mechanical systems as the field- proven Davis Type 778 Stage Cementing Collar.

The packer portion of this tool uses the same element design as the field- proven Davis Type 100 Integral Casing Packer. This element consists of an innertube housed and protected by continuous, mechanically end- anchored, spring-steel reinforcing strips that are leafed on top of each other. These strips are encased in an oil-resistant outer rubber. Expansion is obtained by injecting fluid into the innertube. This injection forces partial un-leafing of the steel strips which in turn stretches the outer rubber until it effects a full-length seal against the bore it is run in, whether cased or open hole.

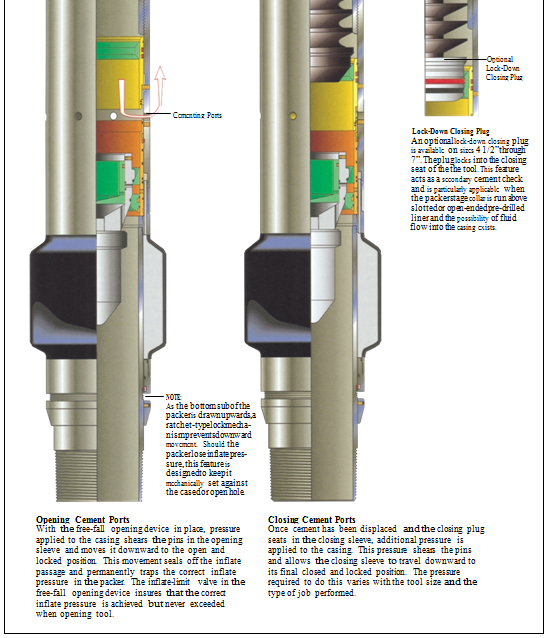

While the packer is expanding, the bottom end of the element is drawn up on a ratchet-type locking mechanism. This feature is intended to keep the element mechanically expanded so it can provide some form of sup- port in the event of hydraulic failure.

Once inflation pressure is reached, simultaneous sealing of the fluid injection inlets and opening of the cementing ports occur. This action allows the immediate introduction of fluid to the annulus after the packer is set. The inflation of the packer also serves to center the tool in the well- bore, leading to uniform distribution of cement as it exits the casing.

Although the combination packer stage collar serves two purposes, it is only one tool. This means that it can be serviced by one person, which eliminates the cost of the second person who would be required if a stage collar and inflatable packer were individually purchased from two separate companies.

The Davis Type 778-100 Packer Stage Cementing Collar has multiple applications. It can be used to:

1. Keep the hydrostatic head of second-stage cement off first-stage cement.

2.Keep the hydrostatic head of second-stage cement off pressure sensitive zones below it.

3. Keep cement from falling around pre-drilled or slotted liners.

4.Selectively place cement across widely separated zones of interest.

5. Prevent gas migration that can ruin primary cement jobs and lead to annular gas problems at the surface and expensive squeeze work.

NOTE: Packer stage collars equipped with six cement ports.1-1/4” diameter on sizes 7” and above, and 1” diameter on smaller sizes. Standard seal length of inflatable packer elements is 36 inches. For special sizes or varying seal lengths consult your nearest Davis representative. Total length of packer stage collar is approximately 120” depending on type threads used.

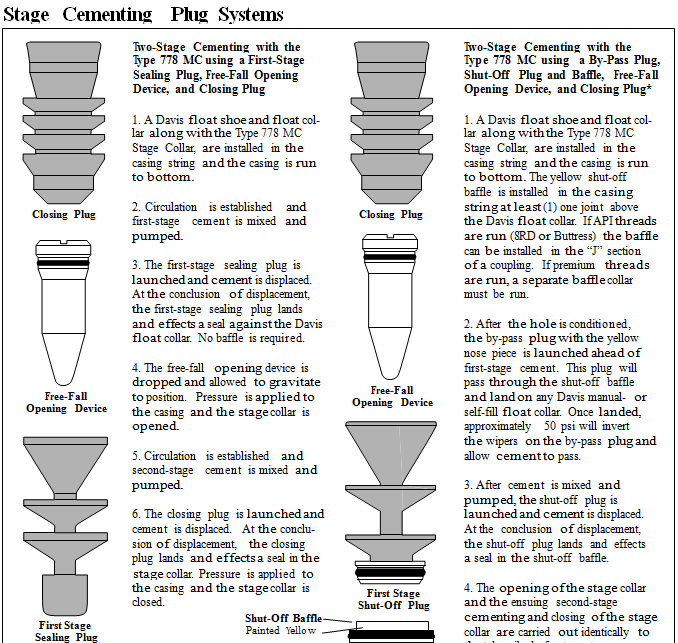

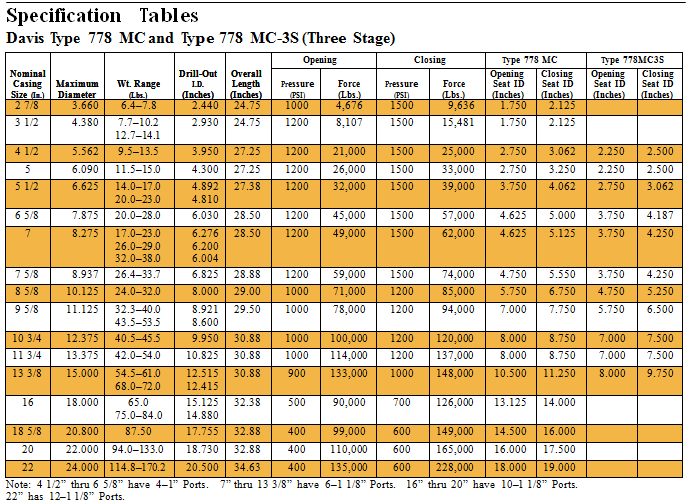

With simple changes to tool IDs and plug and tripping device ODs, all three Davis stage collar designs–the mechanical, the hydraulic and the mechanical with inflatable packer, are made readily available for three-stage applications. See tables for standard sizes. Contact your Davis representative for availability of sizes not shown.

The Type 778-100 Packer Stage Cementing Collar:

Davis Inflatable Packers:

The Davis line of inflatable packers features a weldless design that provides a strong and effective seal. They are available for virtually all drilling, completion and workover requirements, as well as for pipeline testing and repair and offshore platform installation.

Inflatagrip Longseal* Packers

These Davis Packers, available with 20- or optional 40-foot length seals, provide a positive seal against fluid or gas movement in the annulus of vertical, deviated or horizontal wells.They are recommended for use where naturally occurring fracture systems and high permeability streaks require a longer seal for more positive zone isolation. Mud- or cement- filled Inflatagrip Longseal Packers will conform to and seal in washed-out, elliptical or other irregularly shaped well- bores. They are of the limited steel rib reinforcing type in that the ribs do not extend completely from one end of the seal to the other. This feature allows the non-reinforced center portion of the packer to expand and seal in larger, irregularly shaped wellbores and still be retained at the ends by the overlapping steel Inflatagrip reinforcing ribs.

Features/Benefits of Types 202 and 402 Inflatagrip Longseal Packers:

1.Patented Inflatagrip® end reinforcing metal ribs anchor against wall of well for positive end containment during and after inflation.

2. Reinforcing metal ribs mechanically attached at each end of the element, along with the single durometer rubber element, assure a uniform inflation between the metal ribs to displace a maximum amount of mud from the seal area.

3. Mechanical anchoring of reinforcing metal ribs in end subs, together with the Inflatagrip feature, greatly improves the pressure differential holding ability of the packers.

4. Dual inflation valve system provides 56% greater inlet area for the inflation fluid than dual valve systems of competition.

5. Longer reinforcing ribs bonded to a rubber cover, in addition to surface preparation of the mandrel, minimize any wadding of packer element during running.

6. Premium threads are available internally throughout the packers, eliminating the need for welding or the use of crossover sub.

7. No welding or epoxy, which might cause premature failure, is used in manufacturing Davis packers. Unique Application Large Diameter Inflatagrip Longseal Packers.

Davis sales/engineering personnel have designed and implemented a method on several wells in a deepwater-drilling environment, which employs the Inflatagrip Longseal Packers for the purpose of containing troublesome shallow salt-water flows. This system has been utilized on 20” and 16” casing strings at the present time. Packer placement, inflation pressure settings, and the use of specialty float equipment to receive a drop ball have been instrumental in the success of this method. For more complete details please contact your local Davis representative.

Packers with Continuous Reinforcing :

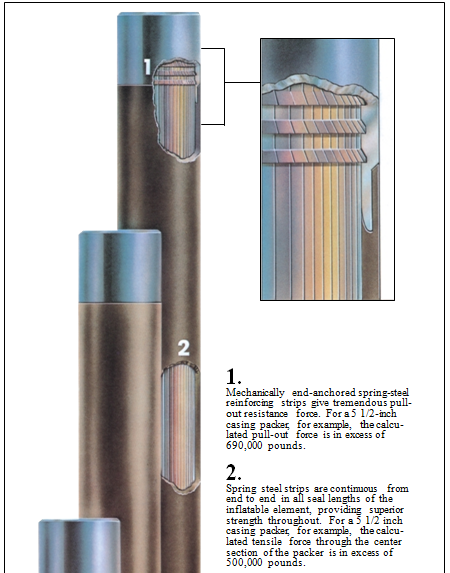

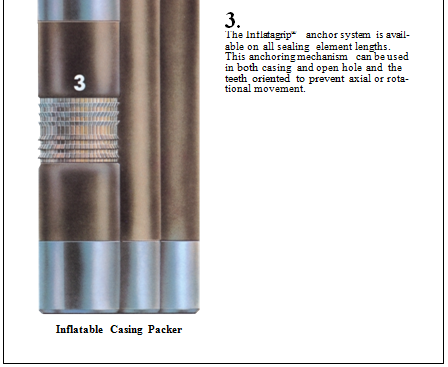

The inflatable element of these packers has steel strips that run from end to end of the seal and are mechanically attached to end subs. Available in standard 3-, 7- and 10- foot lengths, the continuous strip element will centralize the casing in the wellbore and withstand maximum differential pressure. It can be inflated with water, mud or cement. The 7- and 10-foot elements may be preferred for added seal length in fractured or highly permeable zones or where packer placement is critical for success.

The inflatable element consists of an innertube protected by the continuous, mechanically end-anchored, spring-steel reinforcing strips. These strips are totally encased in an oil- resistant outer rubber. Expansion is achieved by injecting fluid into the innertube. The fluid expands the strips, stretching the outer rubber and effecting a full-length seal against the bore wall, in cased or open hole.

Inflatagrip Feature

When it is desirable for a continuous reinforced packer to act as an anchor, Davis recommends its patented Inflatagrip system, which consists of raised grippers stamped into the steel reinforcing strips. The grippers can be profiled so that, when expanded and in contact with the wellbore, they prevent axial or rotational movement, in either cased or open hole. The grippers are heat treated to a hardness that enables them to bite into P-110 grade casing. The anchoring mechanism can be built into any Davis continuous rein- forced packer regardless of diameter.

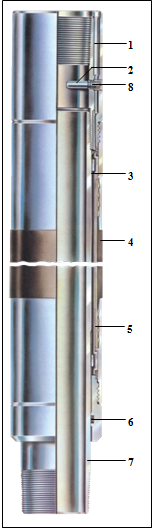

Davis Type 100 Integral Casing Packer:

The Type 100 is a permanent, steel-rein- forced packer that is run as an integral part of the casing string. The mandrel through the packer is the same size, weight, and grade as the casing. The packer is threaded with connections identical to those of the casing string.

The Integral Casing Packer is available with a single sealing element, or with dual straddle elements. It can be run in a multitude of arrangements for numerous applications. When inflated, the packer element will effectively seal between concentric casing strings or between casing and open hole.

This packer can be used to:

1. Control wellbore migration of gas and fluid.

2. Separate multiple zones.

3. Prevent unwanted water intrusion.

4. Allow gravel packing of multiple zones.

5. Reduce hydrostatic pressure during stage cementing.

6. Centralize casing.

Type 100 Integral Casing Packer:

1. Inflation Control Valves

2. Knock-Off Plug

3. Rubber innertube

4. Rubber Outer Cover

5. Flexible Steel Reinforcing

6. Sliding Seal

7. Mandrel (Casing Sub)

8. Screen

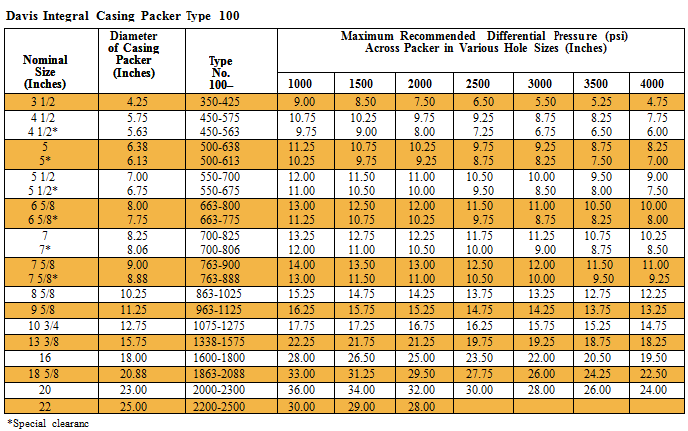

Packer Selection Table:

The Packer Selection Table shows maximum recommended differential pressure across the Integral Casing Packer for any given calipered hole size. For pressure or hole sizes falling between the cited values, the method of interpolation for an approximate value can be used.

The sizes tagged with asterisks are termed “Special Clearance.” They are used where the combination of casing diameter and drilled hole size requires that the diameter of the packer be reduced. These reduced OD sizes are available through special order.

For casing sizes smaller than 3 1/2” and larger than 20”, please consult your Davis representative.